Sensing health parameters of equipment

Communicating health data to central location

Analyzing health data to provide actionable decisions

Dissemination of actionable decisions to all concerned

The Point Machine Health Monitoring Unit(PHMU) decreases maintenance costs and increases the

Point Machine's

availability.

The Battery Health Monitoring Unit (BHMU) is an intelligent system that tracks the health and efficiency of batteries to provide safe guidance and enhance battery capacity.

Signal Lamp

Health Monitoring unit finds unhealthy behaviour of the current regulator before lamp failures and generates alarms

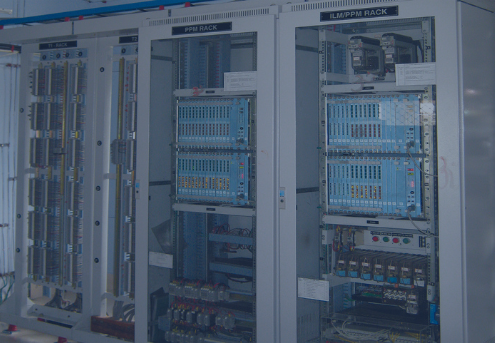

Integrated Power supply is a processor-based system. Its modules have built in processors and standby is available for each module.

DC track circuit health monitoring can be achieved by Monitoring of Feed end current and Relay end current and it can provide useful alarms for MTTR as well as MTBF

Integrated Power supply is a processor-based system. Its modules have built in processors and standby is available for each module.

Interface unit provided on SM room gives audio visual alarm to SM when any axle counter changes to error mode. It gives alarms like another end applied reset while SM did not

Alarms can be generated and brought to a central location after electronic interlocking health or diagnostic data has been extended to the data logger.

Distributed assets exposed to all types of weathers

Sensitive & sophisticated equipment affected by temperature, dust, voltage surges etc.

Rapid introduction of new technologies

Working in multi-departmental environment

Containing the cost of maintenance

Insufficiently skilled personnel for asset maintenance

Ensures availability of signaling system by

Reducing MTTR – by providing insights into incidences

Increasing MTBF– by providing insights into system by - Predictive alarms & Health reports

Deskilling of maintenance activities

Collaborative working with OEMs

Reduction of maintenance effort

Provide data driven decisions